Spotlight On: Scale your product: How do we supply consistent, high-quality versions of your product? With Alastair Graves

Q. What is your academic and professional background?

I started in engineering and manufacturing as soon as I left school, spending a year in industry before studying Engineering Science at the University of Oxford.

After graduation, I joined Caterpillar, specifically Perkins Engines, in Stafford. I spent nearly four years as the engineering owner for the engine test value stream, gaining invaluable experience in both manufacturing best practices and mechanical engineering.

Eventually, I was looking for a new challenge and came across this role at iGii.

Q. How did you come to join iGii?

I wanted a new challenge within the manufacturing sector, and the opportunity to build iGii’s manufacturing lines from the ground up was hard to resist. I also wanted to move away from the heavy manufacturing industry and into a more environmentally conscious field, where my work could help reduce environmental impact, as well as developing more sustainable technologies.

My new role at iGii ticked all these boxes: it’s not often you get the opportunity to build a manufacturing system from scratch, shaping everything from the physical facility to the processes and teams involved.

Q. Can you describe your current role at iGii?

I oversee day-to-day production and planning for future growth. Essentially, my core responsibility is to meet customer requirements (externally and internal R&D teams) as reliably as possible, both today and in months and years to come. This encompasses all current and planned products and manufacturing lines.

My team ensures products are made to meet demand, while colleagues like Mike, focus on developing the next-generation machines that will fit into our production line in the future. I also work closely with the design and development teams to support the development of their new product designs.

While I don’t interact with customers directly, my job is to keep them happy!

What do you find most exciting about the work you do?

iGii’s transformation in the four years since I joined has been incredible. When I started, we had no manufacturing facility at all – just a shell of an office building and some basic floorplans! Over the years, we’ve built a fully functioning production line with defined processes and clear responsibilities. We’re also blessed with the ability to be agile and pivot to changing customer requirements and technological breakthroughs: unlike in a large corporation, we can make decisions one week and implement the next (provided all necessary controls are in place, of course!). That level of influence is rare and incredibly rewarding.

Q. Can you share a specific project or achievement at iGii that you’re particularly proud of?

It’s easy to forget that just a few years ago, we were operating (all R&D and prototype-scale production) out of a single small lab. We now have two facilities, two cleanroom production areas, three labs and a workshop: I’ve been lucky enough to play a role in this journey and I think everyone in iGii should be incredibly proud of the progress we have made. Not only this, but all the supporting systems for production have required design, implementation and validation: no small task!

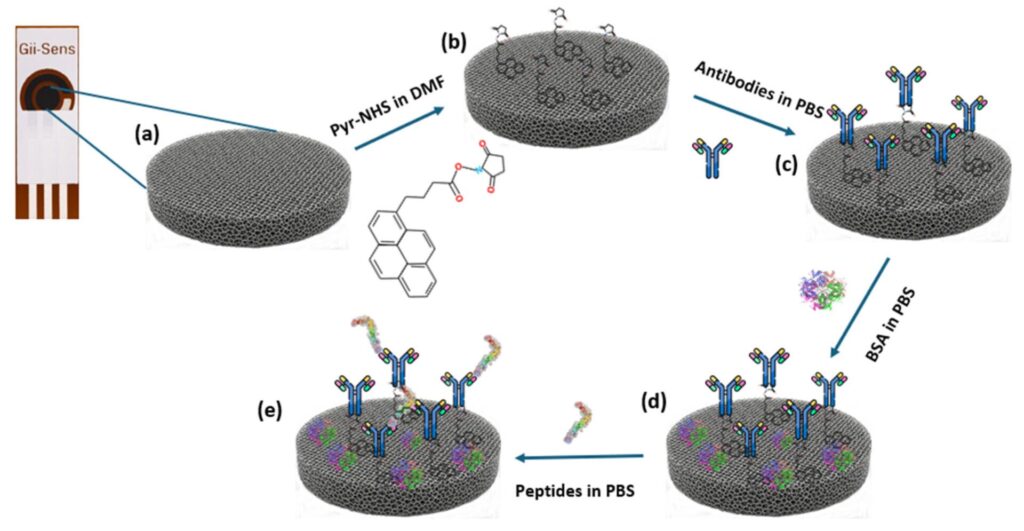

Now, our manufacturing process is inherently scalable. It’s modular and can be deployed wherever there’s electricity, which makes it incredibly versatile. Traditional manufacturing lines are huge, complex operations that often require large facilities. In contrast, we can manufacture Gii in a compact 14-square-metre space. That scalability is one of the most exciting aspects of the technology.

Q. How do you collaborate with other teams or departments?

My role involves constant interaction with different teams, as I manage the diverse requirements of internal customers/departments alongside our commercial customers. We run a daily coordination meeting, but I often need to spend time separately understanding these requirements in more detail, as many internal requests can be very complex!

What skills does iGii have across the business that really stand out?

One of iGii’s biggest strengths is the team’s natural problem-solving ability. We boast an astonishing number of highly qualified scientists and engineers and love getting our teeth into the solving of challenging technical problems!

There’s also a strong culture of ownership and accountability, where people take responsibility for their roles and get things done with minimal supervision. That level of initiative is rare and a key factor in our success.

Q. Are there any upcoming projects or goals you’re particularly looking forward to?

One of the biggest upcoming projects is the roll-out of our reel-to-reel manufacturing process, which will be a major step forward in scaling up production. It will significantly increase our manufacturing capacity and accelerate commercialisation. It’s a huge focus for us and will be a game-changer in how we produce Gii.